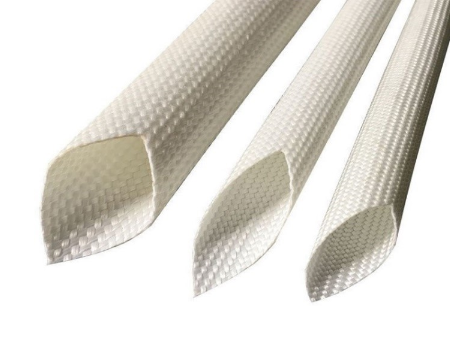

Fiberglass Sleeve

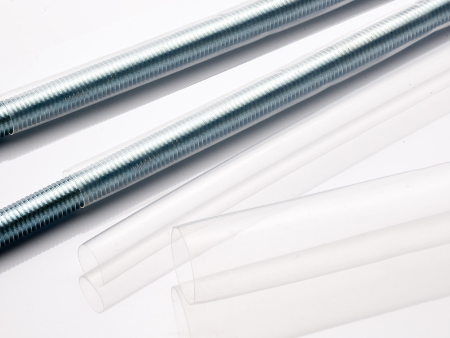

Internal wiring of rotating machines, classes H and C motors, transformers, generators, heating apparatus, lighting automotive, control, etc.

Powered by Froala Editor

Powered by Froala Editor

FEATURES

• It is braided by non-alkali fiberglass, then with and treated in high temperature.

• Flammability: self-extinguishing, good compatibility with same class impregnation varnishes, good mechanical resistance, very flexible.

Powered by Froala Editor

Powered by Froala Editor

TYPICAL APPLICATIONS

Material data: Fiber glass + Flexible silicone rubber

- Operating temperature: -30ºC ~200ºC

- Approvals / specifications: UL 1441 File no. E151045

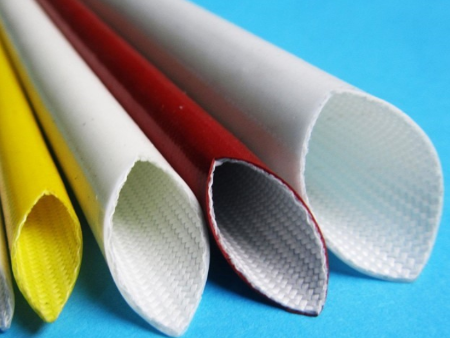

Standard color: Black & white (other color and multi-colors can be customized)

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

TECHNICAL DATA

| Item | Test Method | Result |

| Operating | - | -40ºC~+200ºC |

| Withstand Voltage | AC2500V 60s | No cracking |

| Bendability at low Temperature | -40ºC*4hrs | No cracking |

| Thermal aging test | 250ºC*24hrs | No cracking |

| Flame resistance | UL-1441 | VW-1 |

| Volume Resitivity | ASTMD257 | ≥1011 Ω.cm |

| Aging Resistance | 265ºC*168hrs | No cracking |

| Aging Resistance after heating | 265ºC*168hrs | ≥1/2 original voltage |

| Average breakdown voltage | UL-1441 | 2500V |

| Minimum breakdown voltage | UL-1441 | 1800V |

| Environment Standard | - | ROHS, REACH |

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

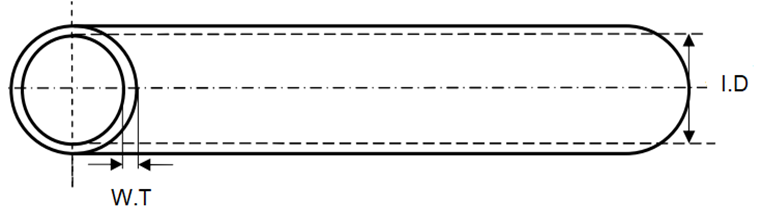

DIMENSIONS

| Part no. | Inside diameter | Wall thickness (mm) W.T | Standard package (m/roll) | |

| Norminal(mm) I.D | Tolerance(mm) | |||

| FSG-2-0010 | 1.0 | +0.3/-0.1 | ≥0.25 | 200 |

| FSG-2-0015 | 1.5 | +0.3/-0.1 | ≥0.25 | 200 |

| FSG-2-0020 | 2.0 | +0.3/-0.1 | ≥0.25 | 200 |

| FSG-2-0025 | 2.5 | +0.3/-0.1 | ≥0.25 | 200 |

| FSG-2-0030 | 3.0 | +0.5/-0.1 | ≥0.27 | 100 |

| FSG-2-0035 | 3.5 | +0.5/-0.1 | ≥0.27 | 100 |

| FSG-2-0040 | 4.0 | +0.5/-0.1 | ≥0.27 | 100 |

| FSG-2-0045 | 4.5 | +0.5/-0.1 | ≥0.27 | 100 |

| FSG-2-0050 | 5.0 | +0.5/-0.1 | ≥0.30 | 100 |

| FSG-2-0060 | 6.0 | +0.5/-0.1 | ≥0.30 | 100 |

| FSG-2-0070 | 7.0 | +0.5/-0.1 | ≥0.30 | 100 |

| FSG-2-0080 | 8.0 | +0.5/-0.1 | ≥0.32 | 100 |

| FSG-2-0090 | 9.0 | +0.5/-0.1 | ≥0.32 | 50 |

| FSG-2-0100 | 10.0 | +0.5/-0.1 | ≥0.35 | 50 |

| FSG-2-0120 | 12.0 | +1/-1.0 | ≥0.35 | 50 |

| FSG-2-0130 | 13.0 | +1/-1.0 | ≥0.35 | 50 |

| FSG-2-0140 | 14.0 | +1/-1.0 | ≥0.35 | 50 |

| FSG-2-0160 | 16.0 | +1/-1.0 | ≥0.35 | 50 |

| FSG-2-0180 | 18.0 | +1/-1.0 | ≥0.42 | 25 |

| FSG-2-0200 | 20.0 | +1/-1.0 | ≥0.42 | 25 |

| FSG-2-0250 | 25.0 | +1/-1.0 | ≥0.47 | 25 |

| FSG-2-0300 | 30.0 | +1/-1.0 | ≥0.47 | 25 |

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor