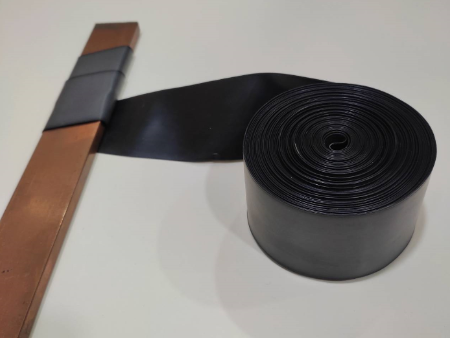

High Voltage Electrical Tape

It is layers, one is heat shrinkable insulation layer, the other is fusible linear-polyolefin layer. As heated the fusible linear-polyolefin layer will melt to seal and insulate the Protected object

Powered by Froala Editor

FEATURES

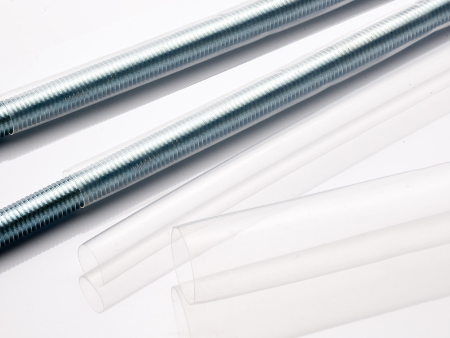

• Insulating protection of threadlike charged body

• Emergent recovery of the power supply

• Partial repair of power cable

• Sealing of the heat shrinkable joint

• Extend insulating distance

• Moist, pollution flashover and erosion resistance

• Prevent short circuit from the icicle when the live wire cross trees or tunnel

Powered by Froala Editor

TYPICAL APPLICATIONS

- Operating temperature: -40°C~100°C

- Installation temperature:-20°C~60°C

Standard color: Black

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

TECHNICAL DATA

| Property | Requirements | Test method | Test result |

| Dielectric strength | ≥20kV | GB/T1408 | 23.5 |

| Power frequency withstand voltage | 42kV/1min (minimum phase spacing30mm) | GB311 | No breakdown |

| Lighting impulse | 75kV/±15min (minimum phase spacing30mm) | GB311 | No breakdown |

| Thermal stability | 4s/31.5kA | GB2706 | No disrepair |

| Dynamic stability | 0.3s/80.0kA | GB2706 | No disrepair |

| Volume resistivity | ≥1.0x1014Ω.m | GB1410 | 8.5x1014Ω.m |

| Dielectric constant | ≤3.5 | GB1409 | 2.3 |

| Oxygen index | ≥28% | GB/T2406 | 28.2 |

| Water absorption | ≤0.1% | GB/T1034 | 0.063% |

| Low temperature flexibility | -55°C±2°C/4h | UL 224 | Pass |

| Erosion resistance | 23±2°C/ humidity: 95% | ASTM D2671 | Pass |

| Tensile strength | ≥12.0MPa | GB/T1040 | 15.3 |

| Ultimate elongation | ≥400% | GB/T1040 | 462% |

| Thermal aging | 136°C/168h | GB/T1040 | Pass |

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

DIMENSIONS

| Part no. | Thickness(mm) | Width(mm) | Standard length(meter) |

| HBR1KV-050 | 0.4 | 50 | 10 |

Powered by Froala Editor

Powered by Froala Editor