High Temperature Heat Shrinkable Tube

Insulation and protection of cables and components exposed to high temperatures and/or solvents, fuels, hydraulic fluids, lubricants, and acids. Suitable for use in engine compartments.

Powered by Froala Editor

FEATURES

• Shrink ratio: 2:1

• High resistance to impact and abrasion

• Resistance to a wide variety of fuels, lubricants, acids, and solvents at elevated temperatures.

• Flexibility at low temperatures without cracking

• Withstand voltage: 600V

• RoHS/ELV compliant

Powered by Froala Editor

TYPICAL APPLICATIONS

Material data: FKM

- Operating temperature: -55˚C~ 200˚C

- Minimum shrink temperature: 100˚C

- Minimum full recovery temperature: 175˚C

Standard color: Black

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

TECHNICAL DATA

| Property | Unit | Performance requirements | Testing method | Test result | |

| Operating temperature | ℃ | -55~200 | UL224 | -55~200 | |

| Specific gravity | g/cm3 | ≤1.90 | ASTM D 792 | 1.89 | |

| Concentricity | % | ≥70 | ASTM D 2671 | 75 | |

| Tensile strength | MPa | ≥8.2 | ASTM D 638 | 11.86 | |

| Breakage elongation | % | ≥250 | ASTM D 638 | 345.23 | |

| 200% elongation | MPa | ≥13.8 | ASTM D 2671 | 10.56 | |

| Cold impact: 4H, -55˚C | \ | No crack | UL224 | -55℃ Pass | |

| Heat shock : 4H, 300˚C | \ | No drip, no flow, no crack | UL224 | Pass | |

| Heat aging 168H, 250±3°C | Tensile strength | MPa | ≥8.2 | UL224 | 11.25 |

| Breakage elongation | % | ≥200 | UL224 | 275.63 | |

| Fluid resistance properties | Tensile strength | MPa | ≥8.2 | ASTM D 2671 | 11.65 |

| Breakage elongation | % | ≥250 | ASTM D 2671 | 285.47 | |

| Breakdown strength | KV/mm | ≥7.9 | ASTM D 2671 | 15 | |

| Volume resistivity | Ohm-cm | ≥1x109 | ASTM D 876 | 1x1013 | |

| Flammability | S | Self-extinguishing within 15seconds | ASTM D 2671 | 0 | |

Powered by Froala Editor

Powered by Froala Editor

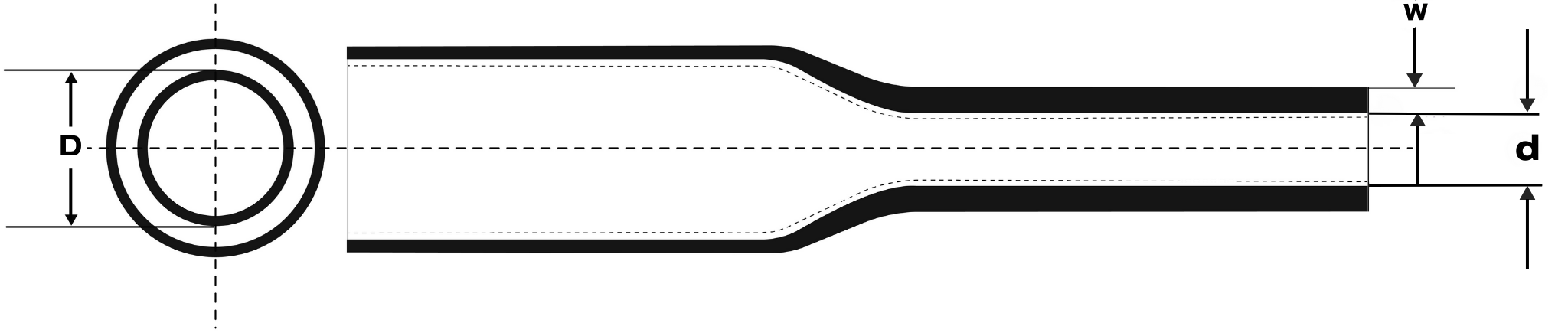

DIMENSIONS

| Part no. | As supplied(mm) | As recovered(mm) | As recovered wall thickness(mm) | Standard length (meter) | ||

| ID(D) | ID(d) | w(min) | w(max) | w(nom) | ||

| SK200-0032 | ≥3.2 | ≤1.6 | 0.65 | 0.90 | 0.78 | 200 |

| SK200-0048 | ≥4.8 | ≤2.4 | 0.70 | 1.07 | 0.89 | 100 |

| SK200-0064 | ≥6.4 | ≤3.2 | 0.70 | 1.07 | 0.89 | 100 |

| SK200-0095 | ≥9.5 | ≤4.7 | 0.70 | 1.07 | 0.89 | 50 |

| SK200-0127 | ≥12.7 | ≤6.4 | 0.70 | 1.07 | 0.89 | 30 |

| SK200-0191 | ≥19.1 | ≤9.5 | 0.86 | 1.27 | 1.07 | 30 |

| SK200-0254 | ≥25.4 | ≤12.7 | 0.97 | 1.52 | 1.25 | 30 |

| SK200-0381 | ≥38.1 | ≤19.1 | 1.00 | 1.78 | 1.40 | 30 |

| SK200-0508 | ≥50.8 | ≤25.4 | 1.22 | 2.08 | 1.65 | 30 |

| Part no. | As supplied(mm) | As recovered(mm) | As recovered wall thickness(mm) | Standard length (meter) | ||

| ID(D) | ID(d) | w(min) | w(max) | w(nom) | ||

| SK200E-0032 | ≥3.2 | ≤1.6 | 0.65 | 0.90 | 0.78 | 200 |

| SK200E-0048 | ≥4.8 | ≤2.4 | 0.65 | 1.00 | 0.83 | 100 |

| SK200E-0064 | ≥6.4 | ≤3.2 | 0.70 | 1.00 | 0.85 | 100 |

| SK200E-0095 | ≥9.5 | ≤4.7 | 0.80 | 1.15 | 0.97 | 50 |

| SK200E-0127 | ≥12.7 | ≤6.4 | 0.90 | 1.35 | 1.13 | 30 |

| SK200E-0191 | ≥19.1 | ≤9.5 | 1.10 | 1.70 | 1.40 | 30 |

| SK200E-0254 | ≥25.4 | ≤12.7 | 1.35 | 2.00 | 1.68 | 30 |

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor