Marking Heat Shrink Tube

SAMS heat shrinkable marker sleeve is designed to satisfy the needs of permanent wire and cable identification. This wire marker sleeve is made from radiation cross-linked heat shrinkable polyolefin, ensuring high durability and flame retardancy. It can be widely used in military, defense, aerospace, marine and other industries.

Powered by Froala Editor

FEATURES

• Shrink ratio: 2:1, 3:1

• Printing: single sided printing or double sided printing

• Supplied format: ladder-style or continuous sleeve

• Recommended printer: thermal transfer printer or laser printer

• Recommended ribbon: N85 resin ribbon, black, 100mm(width)×300m(length)

Powered by Froala Editor

TYPICAL APPLICATIONS

Material data: Fabricated from irradiated, thermally stabilized, flame retarded, modified polyolefin compound

- Operating temperature: -55˚C~+135˚C

- Minimum recovery temperature: +85˚C

- Maximum storage temperature: +50˚C

- Standard: AMS-DTL-23053/5 Class 1&3, SAE-AS 81531, MIL-STD- 202F/Method 215J, UL224, and RoHS.

Standard color: White, yellow, other colors are available upon request.

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

TECHNICAL DATA

| Property | Test method | Typical performance |

| Tensile strength (MPa) | ASTM D2671 | ≥10.3 |

| Tensile strength after aging (MPa) | ASTM D2671 | ≥6.9 |

| Ultimate elongation after aging (%) | ASTM D2671 | ≥200 |

| Ultimate elongation (%) | ASTM D2671 | ≥100 |

| Voltage withstand (V) | UL224 | 2500V, 60s, Pass |

| Dielectric strength (MV/m) | ASTM D2671 | ≥19.7 |

| ASTM D2671 | ≥15.8 | |

| Volume resistivity (Ω·cm) | ASTM D2671 | ≥1014 |

| Water absorption (%) | ASTM D570 | ≤0.5 |

| Corrosion | UL224 | Pass |

| Heat shock | UL224 | No cracks, flowing or dripping |

| Low temperature flexibility | UL224 | No cracks |

| Flammability | UL224 DIN5510-2 | VW-1 |

| Smoke density Ao | BS6853 | NG |

| Index of toxic fume R | BS6853 | NG |

Powered by Froala Editor

Powered by Froala Editor

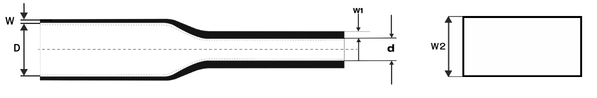

DIMENSIONS

Part no. | As supplied(mm) | As supplied(mm) | Packing quantity Sheet/roll | |||

ID (D) | Flatten width (W2) | Double wall thickness(W) | ID (d) | Single wall thickness (w1) | ||

SAMS-135-2X | ||||||

SAMS-135-2X-0016 | 2.00±0.20 | 3.7±0.3 | 0.48±0.10 | ≤0.79 | 0.45±0.06 | 2500 |

SAMS-135-2X-0024 | 2.79±0.20 | 5.0±0.3 | 0.48±0.10 | ≤1.18 | 0.49±0.06 | 2500 |

SAMS-135-2X-0032 | 3.64±0.23 | 6.3±0.4 | 0.48±0.10 | ≤1.59 | 0.51±0.06 | 2500 |

SAMS-135-2X-0048 | 5.26±0.25 | 8.9±0.4 | 0.49±0.10 | ≤2.36 | 0.54±0.06 | 2000 |

SAMS-135-2X-0064 | 6.92±0.28 | 11.5±0.4 | 0.50±0.10 | ≤3.18 | 0.56±0.06 | 2000 |

SAMS-135-2X-0095 | 10.2±0.32 | 16.7±0.5 | 0.51±0.10 | ≤4.75 | 0.59±0.06 | 1000 |

SAMS-135-2X-0127 | 13.5±0.36 | 21.8±0.6 | 0.52±0.10 | ≤6.35 | 0.60±0.07 | 1000 |

SAMS-135-2X-0190 | 20.1±0.40 | 32.2±0.6 | 0.53±0.10 | ≤9.53 | 0.62±0.07 | 500 |

SAMS-135-2X-0250 | 26.7±0.45 | 42.5±0.7 | 0.55±0.10 | ≤12.7 | 0.63±0.07 | 500 |

SAMS-135-2X-0380 | 39.8±0.51 | 63.2±0.8 | 0.57±0.10 | ≤19.1 | 0.64±0.07 | 500 |

SAMS-135-2X-0510 | 53.0±0.56 | 83.9±0.9 | 0.58±0.10 | ≤25.4 | 0.64±0.08 | 250 |

SAMS-135-2X-0760 | 79.4±0.56 | 125.3±1.0 | 0.59±0.10 | ≤38.1 | 0.64±0.09 | 250 |

SAMS-135-3X | ||||||

SAMS-135-3X-0016 | 2.00±0.20 | 3.7±0.3 | 0.47±0.10 | ≤0.53 | 0.52±0.06 | 2500 |

SAMS-135-3X-0024 | 2.79±0.20 | 5.0±0.3 | 0.47±0.10 | ≤0.79 | 0.57±0.06 | 2500 |

SAMS-135-3X-0032 | 3.64±0.23 | 6.3±0.4 | 0.48±0.10 | ≤1.06 | 0.61±0.06 | 2500 |

SAMS-135-3X-0048 | 5.26±0.25 | 8.9±0.4 | 0.49±0.10 | ≤1.59 | 0.67±0.06 | 2000 |

SAMS-135-3X-0064 | 6.92±0.28 | 11.5±0.4 | 0.50±0.10 | ≤2.36 | 0.71±0.06 | 2000 |

SAMS-135-3X-0095 | 10.2±0.32 | 16.7±0.5 | 0.52±0.11 | ≤3.18 | 0.77±0.06 | 1000 |

SAMS-135-3X-0127 | 13.5±0.36 | 21.8±0.6 | 0.53±0.11 | ≤4.75 | 0.80±0.07 | 1000 |

SAMS-135-3X-0190 | 20.1±0.40 | 32.2±0.6 | 0.55±0.11 | ≤6.35 | 0.84±0.07 | 500 |

SAMS-135-3X-0250 | 26.7±0.45 | 42.5±0.7 | 0.56±0.12 | ≤8.47 | 0.86±0.07 | 500 |

SAMS-135-3X-0380 | 39.8±0.51 | 63.2±0.8 | 0.57±0.12 | ≤12.9 | 0.89±0.07 | 500 |

SAMS-135-3X-0510 | 53.0±0.56 | 83.9±0.9 | 0.57±0.10 | ≤17.2 | 0.90±0.08 | 250 |

SAMS-135-3X-0760 | 79.4±0.56 | 125.3±1.0 | 0.57±0.13 | ≤25.8 | 0.92±0.09 | 250 |

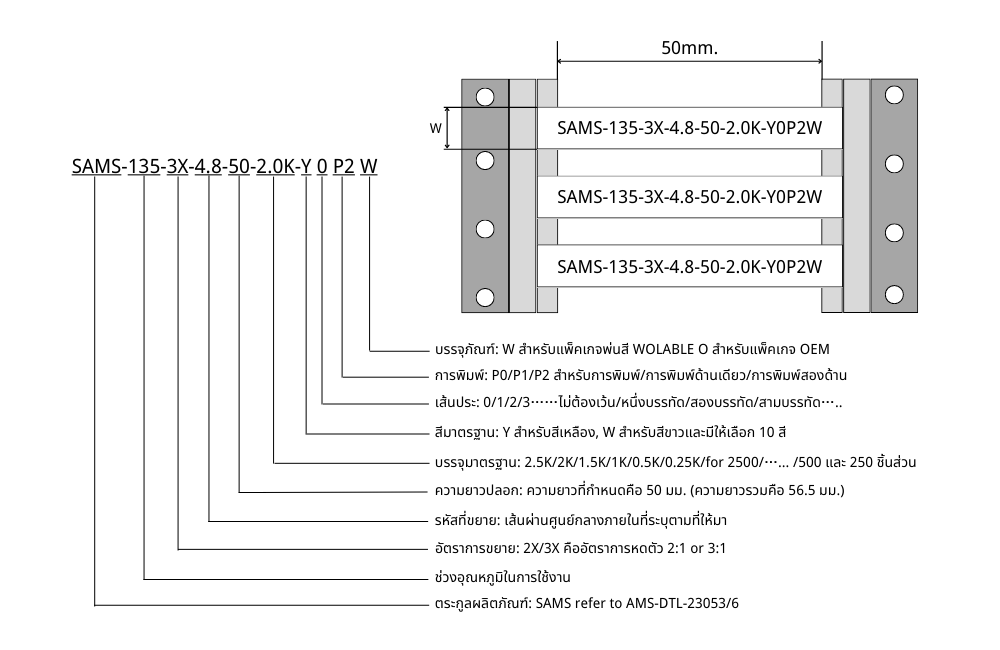

Part Numbering System

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor