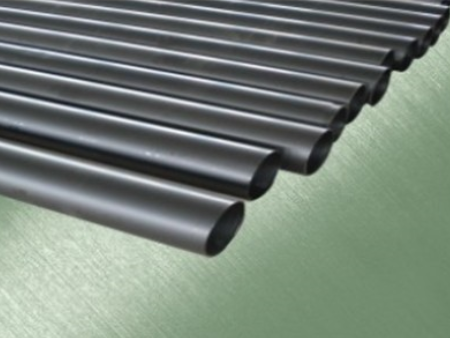

Dual Wall Adhesive-Lined Polyolefin Tubing

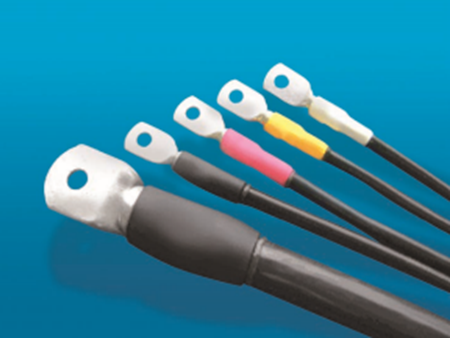

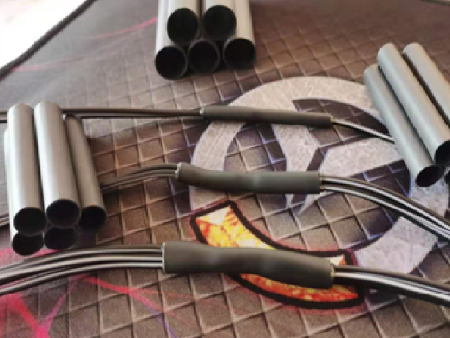

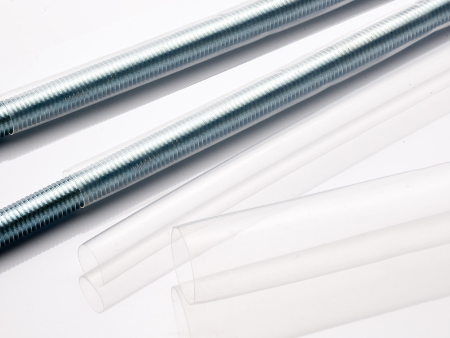

Dual-wall adhesive-lined heat shrinkable tubing is made by co-extrusion of excellent polyolefin compounds and hot-melt adhesive. It is used for water-proofing and insulation protection of wire and cable and wire harnesses, and connector-to-cable transitions. It is typically used in the insulation and sealing of electrical and electronic components, automotive and communication industry. Electrical and electronic components Refrigerator copper &aluminum, automotive and communication industry.

Powered by Froala Editor

FEATURES

• Shrink ratio: 3:1

• Good hot-melt adhesive and high expansion ratio to provide good sealing protection.

• EVA hot melt adhesive for cooper and aluminium.

• Environmental sealing and protection of electrical applications.

• Flexible, flame retardant

• RoHS and REACH compliant

Powered by Froala Editor

TYPICAL APPLICATIONS

Material data: Polyolefin

- Operating temperature: -40°C~125°C

- Minimum shrink temperature: 110°C

- Minimum fully recovery temperature: 150°C

Standard color: Black, white, red, yellow, blue, green, grey (Other colors are available upon request)

Powered by Froala Editor

Powered by Froala Editor

TECHNICAL DATA

| Property | Requirement | Test method | Test result |

| Longitudinal shrinkage | ≤10% | ASTM D 2671 | ≤5% |

| Tensile strength | ≥10.4 MPa | ASTM D 2671 | ≥14 MPa |

| Elongation at break | 200% min. | ASTM D 2671 | ≥400% |

| Tensile strength after ageing (158℃,168hrs) | ≥7.3 MPa | ASTM D 2671 | ≥13 MPa |

| 100% min. | ASTM D 2671 | ≥300% | |

| Heat shock (200℃,4hrs) | No crack | ASTM D 2671 | No crack |

| Low-temperature flexibility (-55℃,4hrs) | No crack | ASTM D 2671 | No crack |

| Dielectric voltage withstand | 2500V,60sec, no breakdown | ASTM D 2671 | No breakdown |

| Volume resistivity | ≥1012 Ω•cm | ASTM D 876 | ≥1014Ω·cm |

| Flammability | VW-1 | UL 224 | Pass |

Powered by Froala Editor

Powered by Froala Editor

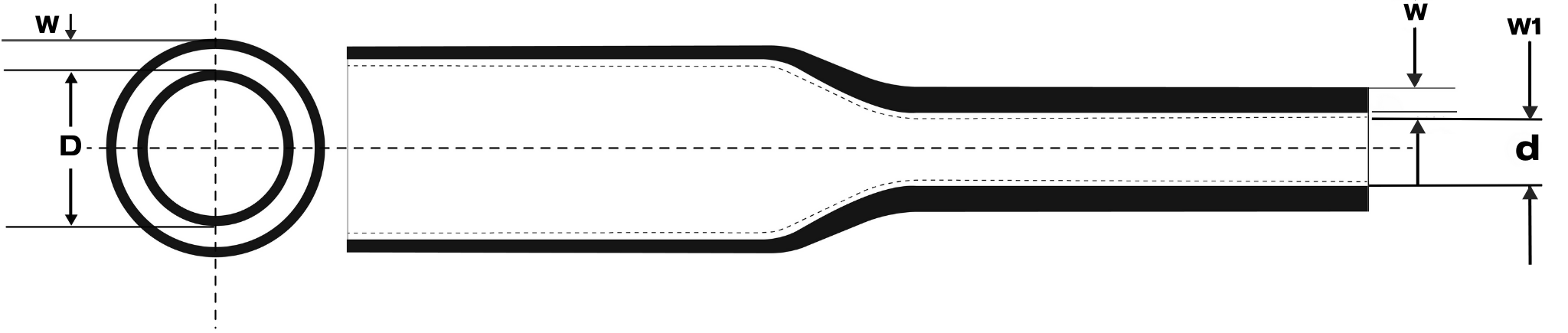

DIMENSIONS

| Part no. | Size(mm) | As supplied(mm) | After shrinkage(mm) | Standard package(m/pcs) | |||

| ID(min) (D) | W.T(W) | ID(max) (d) | Total W.T(w) | Adhesive thickness(w1) | |||

| SDW-(3CA)-0048 | 4.8 | ≥4.8 | 0.45 | ≤1.60 | 1.10±0.25 | 0.5 | 100 |

| SDW-(3CA)-0100 | 10.0 | ≥10.0 | 0.55 | ≤3.00 | 1.35±0.25 | 0.6 | 1.22 |

| SDW-(3CA)-0127 | 12.7 | ≥13.0 | 0.55 | ≤4.00 | 1.35±0.25 | 0.6 | 1.22 |

| SDW-(3CA)-0150 | 15.0 | ≥15.0 | 0.60 | ≤5.00 | 1.55±0.30 | 0.6 | 1.22 |

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor

Powered by Froala Editor